- Advanced Manufacturing

- Biotechnology

- Business

- Communication, Social Sciences, Art & Humanities

- Construction & Maintenance

- Education

- Engineering

- Health Care & Wellness

- Hospitality & Personal Services

- Information & Digital Technology

- Public Safety

- Science & Math

- Transportation

- Propel

- Apprenticeships

- Non-degree Online Learning

- Adult Learners

- Entrepreneurship & Small Business Center

- En Español

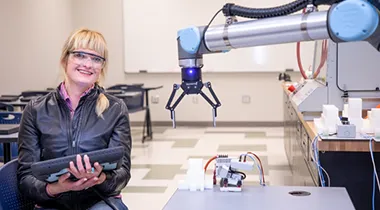

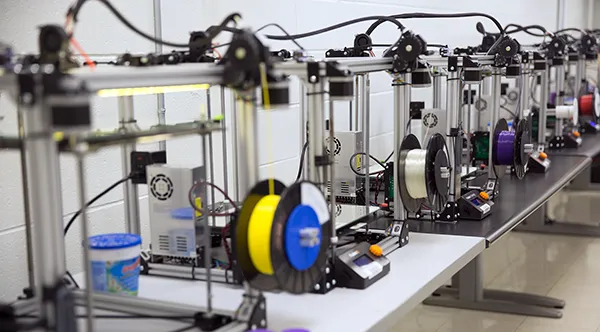

Learn how to program and operate robotic equipment in a manufacturing facility, or gain skills such as 3D printing, machining and more.

Engineering Career Field Courses

Collaborative Robotics Technician Level 1

- Course ID: MEC-3010K1

- Overview

- Course Outline

- Requirements

- Intended Audience

- More Details

Course Objectives

Have an understanding of workplace safety including maintaining an awareness of the work environment, ensuring it's cleanliness, identifying potential hazards, awareness of emergency procedures and emergency exit routes. Students will also receive training on personal protective equipment (PPE), as well as basic safety precautions for working with robots.

Have an understanding of safety functionality, including the safe use of tools and machinery. Students will learn the importance of checklists when operating equipment and machinery.

Understand Blueprints and how to read them. Successful students should be able to read a basic blueprint and determine the critical features of a part to ensure proper installation and that quality standards are being met.

Have an understanding of basic electrical theory including electrical terminology and fundamental measures. Topics covered include Ohm's law, Watt's Law, amperage, voltage, resistance, and wattage. Students will also learn the basics of electrical hazards and safe work practices.

Have an understanding of the basics of programmable logic controllers (PLC's), their functions and operation. Students will learn the different types of PLC's and develop a basic understanding of how they are programmed.

Have an understanding of basic pneumatic theory. Students will learn the different components of pneumatic power systems, how they function and how pneumatics are integrated into Robotic systems.

Have an understanding of the most common applications of industrial automation and collaborative robotics, and how they work together. Students will learn basics of robotic components, including arms, end effectors and axes. Students will understand how axes are used to control robot movement.

Develop an understanding of sensors that provide feedback data to robots and be able to explain the categories of sensors and show how sensors are used in industrial and collaborative robotics.

Have learned the basics of robotic connectivity, including proper electrical and pneumatic connections, verification of connections, and how to make adjustments.

Develop an understanding of the fundamental concepts required for programming collaborative robots, including the use of the Pendant Controller, and Reteach Points. Students will create a program, install the program, save it, and backup the system.

Know the robot machine modes (automatic and manual), understand when each should be used, and know how to switch from one to the other quickly in the event of an emergency. Students will also understand how to operate the robot at variable speeds to identify mechanical issues and ensure the robot is operating safely in the work environment.

Develop a working understanding of the troubleshooting process and how to identify problems, including quality control issues, and their causes.

Learn how to start, stop, and clear errors that might occur during the operation of the robot, and develop an understanding of why the errors might have occurred.

Learn how to recover from a robot crash, understand why the crash occurred, and evaluate the robot to ensure the crash did not damage the system.

Gain a working understanding of the importance of maintenance, as well as when to call in a Maintenance Technician for repairs.

Learn the importance of personal interaction with customers and co-workers. Students will understand the need to focus on customer service and satisfaction.

Outline of Instruction

Contact Hours

132

CEUs

No

Industry Standard, State or National Certification

Certification

FANUC HandlingTool Operation and Programming Certification and/or Smart Automation Certification Alliance

Website

fanucamerica.com; saca.org

Certification Learning Outcomes/Requirements

FANUC:

1. Robot safety and safety devices

2. Robot systems and components

3. Initial robot installation and start up

4. Basic robot operations using teach pendant

5. Basic robot programming

6. Program file manipulations

7. Robot integration

8. Troubleshooting system errors

9. Simulations for robots

SACA:

1. Electrical System Safety, Electrical Circuits, Electrical Diagrams and Measurements, Electrical Circuits

2. Electrical Motor Controls

3. Pneumatic Systems

4. Pneumatic Troubleshooting

5. Programmable Controller Systems

6. Programmable Controller Troubleshooting

CE or CU Articulation

No

Prerequisites

Basic math and general computer skills

Learning Supplies Needed

Student guides, Collaborative Robots, Robotics Systems training panels and associated tools and equipment

Clinical Site/Special Facilities

Advanced Manufacturing Center.

Requirements for Successful Completion

90% attendance

Completion of all modules with a minimum score of 75% for each module.

Accreditation/Special Approval Requirements

N/A

Intended Audience

This course is intended for personnel who wish to be employed in an industry position that utilizes Collaborative Robotics Operators

Specific Industry or Business Support Needs

Robotics Operator

Wake County Need for Industry Positions

This is a skills gap area for light manufacturing in Wake County that is dependent on skilled robotics operators to keep manufacturing systems operating.

Industry or Job Titles Related to Training Outcomes for Employment

Robotics Operator

No active courses available at this time.

To be notified when this course becomes available, please use

Wake Tech's Notify Me service.